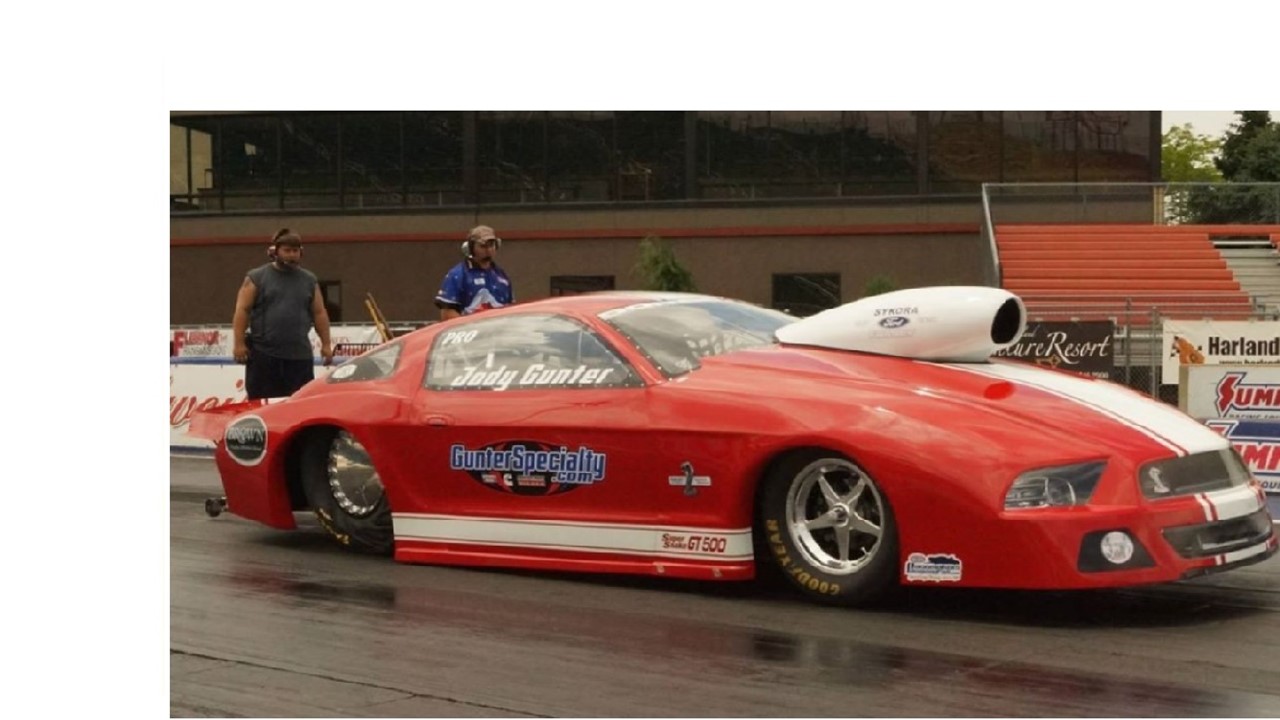

Numerous Record Holders!

When Speed is Required

Unequalled Performance!

Pushing the Limits

Shock & Awe!!

Sheer Excellence

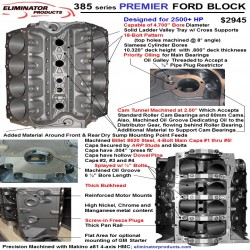

Equations and charts to assist in achieving your performance goals

446 English Rd,

Building 2,

Rockwall, TX 75032

Phone: (248) 408-4949

Email: eliminatorproducts1@gmail.com

Download White Papers

Download White Papers